- Split

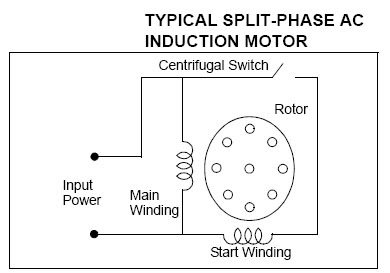

phase induction motor has two windings its stator, a main winding and an

auxiliary winding or starting winding. The starting winding is located 90o

electrical from the main winding and operates for a short time when the

motor starts up.

- The

two windings are so designed that the starting winding has a high

resistance and relatively small reactance while the main winding has

relatively low resistance and large reactance. This can be done by having

main winding of large diameter and number of turns while starting winding

of a fine wire of a small number of turns. The currents taken by these two

windings are out of phase (25o to 30o). Schematic

diagram and phasor diagram of split phase induction motor are shown in

figure

- Operation: When the stator windings are

energised from a single phase supply, the main winding carries current Im

and the starting winding carries current Is. These two currents are out of

phase (25o to 30o) and produce a weak rotating field

which starts the motor. The starting torque is given as,

Ts = K Im Is

Sin Ф

Where

K = constant whose magnitude depends

upon the design of the motor

When

the motor reaches about 75% of synchronous speed, then the centrifugal switch

or relay opens the circuit of the starting winding. The motor then operates as

a single-phase induction motor and continues to accelerate till it reaches the

normal speed. The normal speed is below the synchronous speed and depends upon

the load on the motor.

Characteristics

of Split-Phase I / M:

- The

starting torque is 1.5 to 2 times the full load torque and the starting

current is 6 to 8 times the full-load current.

- The

power ratings of such motors are from 60 Watts to 250 Watts.

- They

have efficiency of 50 – 70 % and overload of 50%.

- As

they have moderate starting torque and low starting current, so they are

commonly used to drive fans, blowers, centrifugal pumps, domestic

refrigerators, washing machines, oil burners, small machine tools, etc.

- These

motors are essentially constant-speed motors. The speed variation is 2 to

5 % from no-load to full-load.

- The

speed range of such motors is from 2875 to 700 r.p.m.

- Such a

motor can be operated with a power factor of 0.55 – 0.65.

- The

percent slip for such motors is about 4 – 6 percent.

This is such a wonderful comprehensive article. You deserve an award for best manufacturer of AC Motor India..!!

ReplyDeleteAC Motor India

AC / DC Motors

Hi,

ReplyDeleteGreat post! Thanks you so much for the share. It is indeed a helpful one. I am looking forward of reading more article with the similar topic as this one. Good luck and More Power.

Induction Machine

Thanks for sharing your info. I really appreciate your efforts and I will be waiting for your further write ups thanks once again.........Induction Machine of Sunnerindia is now very popular product in India and also worldwide. Due its quality, durability and low cost it is mostly used by people and service industries. Our motto is to establish our brand image-for right application in every industry in our country and developing nations in the world.

ReplyDeleteInduction Machine

UDAY ENTERPRISES offering Automatic or fully programmable motor Coil Winding Machine in Delhi , India . Get high performance winding machine at competitive price from UDAY ENTERPRISES.

ReplyDeleteCall @ +91-9212320224

Website: http://www.coilwindingmachine.co.in

Address: 432, Nayaye Khand – 1, Indirapuram Ghaziabad, UP. - 201010

Thanks for sharing good valuable post..........!

ReplyDeleteSunner Republic of India doing the services square measure Fabrication Machine, Tube improvement Machine, Glass Grinding Machine and sharpening Machine. Now versatile Shaft Grinder is our one in all the simplest userfriendly product in Republic of India for its quality, sturdiness and energy saving.

Renowned Engineers Private Limited

Puzhal, Chennai - 600 066

Phone: 044 26591002/3/4/5

Telefax: 044 26590260

E-mail: enquiry@sunnerindia.org

M/s Renowned Engineers Private Limited is a successful organisation run by efficient and expert professionals.Sunner India Flexible Shaft Machines have stood the test of time both in quality and performance in our country and devolping nations too; to name a few destinations

For more information log on to :- Flexible Shaft Grinder

Hi can I know why centrifugal switch need to be open at 75-80% of synchronous speed?

ReplyDelete