Q1: Where

do we require single-phase induction motors?

Ans:

Single-phase induction motors are required where

(i) 3 phase

supply is not available

(ii) efficiency is of lesser importance

(iii) Rating

is less than one H.P.

(iv) Equipment is portable

Q2:

Why is the power factor of a single-phase induction motor low?

Ans:

It is due to the large magnetizing current which ranges from 60% to 70% of

full-load current. As a result, even at no-load, these motors reach

temperatures close to the full-load temperature.

Q3:

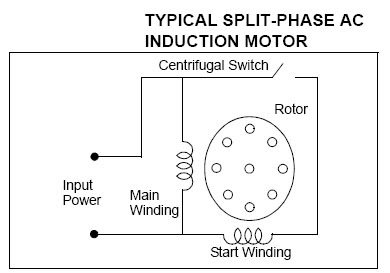

What is the function of centrifugal starting switch in a single-phase induction

motor?

Ans:

The centrifugal switch is connected in series with the starting winding. The

primary function of the centrifugal switch is to produce rotating flux in

conjunction with main winding at the time of starting. When the motor has

started and reaches nearly 75% of synchronous speed, it produces its own

rotating field from the cross field effect. The starting winding now has no

function to perform and is removed from the circuit by a centrifugally operated

switch.

Q4:

What happens when the centrifugal starting switch fails to open?

Ans:

If the starting switch fails to open when needed, then the starting winding

will overheat and burn out and motor will not start next time.

Q5:

What happens when the centrifugal switch fails to close when needed?

Ans:

If the centrifugal starting switch fails to close, the motor will overheat the

main winding without any failure of the main winding.

Q6:

Why are resistance split-phase inductions motors most popular?

Ans:

These motors are most popular due to their low cost. They are used where

moderate starting torque is required and where the starting periods are not

frequent. They drive fans, pumps, washing machines, small machine tools etc.

They have power ranting between 60 watts and 250 watts.

Q7:

What is the draw back of the resistance split-phase induction motor?

Ans:

The starting winding has a relatively small number of turns of fine wire and

its resistance is higher than that of the main winding. Therefore the current

density is high and the winding heats up quickly. If the starting period lasts

for more than 5 seconds, the winding begins to smoke and may burn out unless

the motor is protected by a built-in-thermal relay.

Q8:

Why is the starting torque of a resistance split-phase induction motor not

high?

Ans:

The starting torque is given as, Ts = K Im Is Sin Ф

Where

K = constant whose magnitude depends

upon the design of the motor

(i)

The angle between Is and Im is small (approximately 25 degree) in a resistance

split-phase induction motor, so the starting torque is small.

(ii)

Since currents Is and Im are not equal in magnitude, the rotating magnetic

field is not uniform and the starting torque produced is small.

Q9:

Why is the starting torque of a capacitor start induction motor high?

Ans:

The capacitor C in the starting winding is so chosen that Is leads Im by 75

degree. Since the starting torque is directly proportional to Sin Ф, and it is

quite high in capacitor-start induction motor.

Q10:

Why do we use capacitor-start induction motors in applications requiring high

starting torque in preference to repulsion induction motors?

Ans:

Capacitors are easily available, cheaper and reliable. Repulsion-induction

motors posses a special commutator and brushes that require maintenance. Most

manufacturers have stopped making them.

Q11:

What is the principle of operation of shaded-pole induction motor?

Ans:

A shaded-pole motor is basically a small single-phase squirrel cage motor in

which the starting winding is composed of short-circuited copper ring (called

shading coil) surrounding one-third of each pole. The effect of the shading

coil is to cause a flux to sweep across the pole faces, from unshaded to shaded

portion of the pole, producing a weak rotating magnetic field. As a result, the

rotor is set in motion due to induction principle.

Q12:

Which type of torque is developed in single phase motors?

Ans:

Pulsating torque is produced.

Q13:

If a single phase motor is driven in any direction by any means, it starts

running in that direction. Explain why?

Ans:

Actually a pulsating torque has two components which are equal in magnitude and

rotate in opposite direction with synchronous speed at unity slip. Now if the

motor rotates in any direction, the slip decreases and the torque component in

this direction increases than the other component and hence motor runs in that

direction.

Q14:

What is a fractional H.P. motor?

Ans:

A small motor having H.P. less than unit is called fractional H.P. motor.

Q15:

Which type of rotor is used in single phase motors?

Ans:

Squirrel cage type

Q16:

How the starting winding produce rotation in a single phase resistance start

induction motor?

Ans:

The starting winding is highly resistive and the main winding is inductive. So

the phase difference between the two currents becomes nearly 90 degree and

hence the motor start as two phase motor.

Q17:

How the starting winding is made resistive?

Ans:

It consists of only few turns of smaller diameter.

Q18:

How the speed of rotation of a split phase induction motor is reversed?

Ans:

The terminal connections of the starting windings are reversed with respect to

main running windings.

Q19:

What will happen if the centrifugal switch fails to open the starting winding?

Ans:

Excessive heat will be produced due to high resistance of the starting winding due

to which stator temperature will rise and eventually both windings will burn.

Q20:

How speed control is made in single phase motors?

Ans:

It is usually controlled by applying a variable voltage from tapped

transformers, variacs, potentio meters, and tapped reactors.

Q21:

Is there any relation between the capacitances of two capacitors used in two

value capacitor motor?

Ans:

Starting capacitor has about 10 – 15 times high capacity than the value of

running capacitor.

Q22: What is size of shaded-pole motor?

Ans:

These are usually built in small fractional H.P, not exceed 1/4 H.P.

Q23:

Why shaded-pole single phase induction motor does not need any special starting technique like capacitors

and auxiliary winding etc.

Ans:

Because it is inherently self started motor. The construction of the poles is

such that they give a sweep to the magnetic flux and motor starts rotating.

Q24:

How can a universal motor be reversed?

Ans:

By reversing either the field leads or armature leads but not both.

Q25:

What are applications of Stepper motors?

Ans:

(i) Paper feed motors in typewriters and printers

(ii) Positioning of print

heads

(iii) Pens in XY-plotters

(iv) Recording heads in computer disc drives

etc.

Q26:

Why do we use capacitor-start induction motors in applications requiring high

starting torque in preference to repulsion induction motors?

Ans:

Capacitors are easily available, cheaper and reliable. Repulsion-induction

motors posses a special commutator and brushes that require maintenance. Most

manufacturers have stopped making them.

Q27:

If a single phase motor is driven in any direction by any means, it starts

running in that direction. Explain why?

Ans:

Actually a pulsating torque has two components which are equal in magnitude and

rotate in opposite direction with synchronous speed at unity slip. Now if the

motor rotates in any direction, the slip decreases and the torque component in

this direction increases than the other component and hence motor runs in that

direction.

Q28:

What is a fractional H.P. motor?

Ans:

A small motor having H.P. less than unit is called fractional H.P. motor.

Q29:

Which type of rotor is used in single phase motors?

Ans:

Squirrel cage type

Q30:

How the starting winding produce rotation in a single phase resistance start

induction motor?

Ans:

The starting winding is highly resistive and the main winding is inductive. So

the phase difference between the two currents becomes nearly 90 degree and

hence the motor start as two phase motor.

Q31:

How the starting winding is made resistive?

Ans:

It consists of only few turns of smaller diameter.

Q32:

How the speed of rotation of a split phase induction motor is reversed?

Ans:

The terminal connections of the starting windings are reversed with respect to

main running windings.

.jpg)